Commercial Applications

- Properties, History and Challenges

- Overview

- Electric Power

- Transportation

- Medical Imaging and Diagnostics

- NMR for Medical and Materials Applications

- Industrial Processing

- High Energy Physics

- Wireless Communications

- Instrumentation, Sensors, Standards and Radar

- Large-Scale Computing

- Renewable Energy

- Cryogenics: An Enabling Technology

Properties, History, and Challenges

Superconductors differ fundamentally in quantum physics behavior from conventional materials in the manner by which electrons, or electric currents, move through the material. It is these differences that give rise to the unique properties and performance benefits that differentiate superconductors from all other known conductors.

Unique Properties

- Zero resistance to direct current

- Extremely high current carrying density

- Extremely low resistance at high frequencies

- Extremely low signal dispersion

- High sensitivity to magnetic field

- Exclusion of externally applied magnetic field

- Rapid single flux quantum transfer

- Close to speed of light signal transmission

Zero resistance and high current density have a major impact on electric power transmission and also enable much smaller or more powerful magnets for motors, generators, energy storage, medical equipment and industrial separations. Low resistance at high frequencies and extremely low signal dispersion are key aspects in microwave components, communications technology and several military applications. Low resistance at higher frequencies also reduces substantially the challenges inherent to miniaturization brought about by resistive, or I2R, heating.

The high sensitivity of superconductors to magnetic field provides a unique sensing capability, in many cases 1000x superior to today's best conventional measurement technology. Magnetic field exclusion is important in multi-layer electronic component miniaturization, provides a mechanism for magnetic levitation and enables magnetic field containment of charged particles.

The final two properties form the basis for digital electronics and high speed computing well beyond the theoretical limits projected for semiconductors. All of these materials' properties have been extensively demonstrated throughout the world.

History of Superconductor Materials

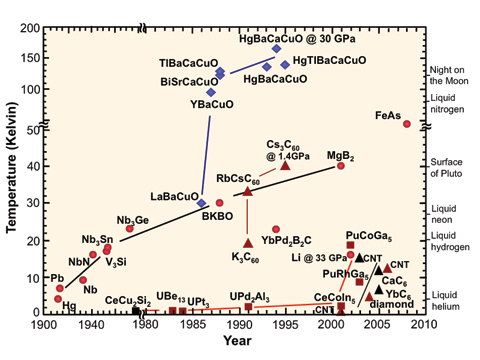

In 1911, H. K. Onnes, a Dutch physicist, discovered superconductivity by cooling mercury metal to extremely low temperature and observing that the metal exhibited zero resistance to electric current. Prior to 1973 many other metals and metal alloys were found to be superconductors at temperatures below 23.2 K. These became known as Low Temperature Superconductor (LTS) materials.

Since the 1960s' a Niobium-Titanium (Ni-Ti) alloy has been the material of choice for commercial superconducting magnets. More recently, a brittle Niobium-Tin intermetallic material has emerged as an excellent alternative to achieve even higher magnetic field strength.

In 1986, J. G. Bednorz and K. A. Müller discovered oxide based ceramic materials that demonstrated superconducting properties as high as 35 K. This was quickly followed in early 1987 by the announcement of C. W. Chu of a cuprate superconductor functioning above 77 K, the boiling point of liquid nitrogen.

Since then, extensive research worldwide has uncovered many more oxide based superconductors with potential manufacturability benefits and critical temperatures as high as 135 K. A superconducting material with a critical temperature above 23.2 K is known as a High Temperature Superconductor (HTS), despite the continuing need for cryogenic refrigeration for any application.

Challenges

- Cost

- Refrigeration

- Reliability

- Acceptance

Forty years of development and commercialization of applications involving LTS materials have demonstrated that a superconductor approach works best when it represents a unique solution to the need. Alternatively, as the cost of the superconductor will always be substantially higher than that of a conventional conductor, it must bring overwhelming cost effectiveness to the system.

The advent of HTS has changed the dynamic of refrigeration by permitting smaller and more efficient system cooling for some applications. Design, integration of superconducting and cryogenic technologies, demonstration of systems cost benefits and long term reliability must be met before superconductivity delivers on its current promise of major societal benefits and makes substantial commercial inroads into new applications.